Really should you coat in-home? Things to think about consist of expenses, provide chain troubles and the capability to make proprietary coatings

When we final coated reducing resource coatings in element (ME August 2019: “Better Instrument Life by means of Advanced Chemistry”), the very hot new technologies was higher-energy impulse magnetron sputtering (HiPIMS). HiPIMS is an highly developed sort of bodily vapor deposition (PVD) that achieves a almost complete ionization of the coating metallic. But the system calls for controlling a lot more than 100 parameters. At the time, instrument companies were being just starting to identify the benefits of coatings created by the method—but lots of nevertheless ended up leery about attempting it themselves.

CemeCon, a coatings technological innovation provider centered in Horseheads, N.Y., now gives devices that can be operated by new users immediately after just a handful of weeks of training—and these methods are even extra able than before products, according to Gross sales Manager Ryan Lake.

The company’s most current operating application makes it reasonably uncomplicated to management the multitude of aspects that govern the HiPIMS course of action, Lake stated. He recounted a the latest set up in which a client despatched staff members to CemeCon for two-7 days education classes, adopted by yet another two weeks in-property. “None of them had ever performed coating before, nevertheless they ended up [soon] up and jogging.” As he set it, CemeCon is “able to practice everyone that has curiosity in the technologies. If they can determine out how to effectively make high quality reducing tools, they can find out how to do coating.”

Should You Acquire Coating In-Dwelling?

Specialty resource manufacturer and regrinder Improved Edge, Scottdale, Pa., coats its item with devices from CemeCon and Liechtenstein-based Oerlikon Balzers. Plus, Superior Edge’s Kabrlyn Coating Systems division delivers coating products and services to other software companies. Similarly, CemeCon, Balzers and other corporations that make coating vessels generally offer coating as a support, way too, and these firms can supply practical perspectives on no matter whether to acquire coating in-property.

Lake reported the initially of three components to review is economical: How a lot are you paying out on outside the house coating providers? “If it’s $200,000 to $250,000 for every year, there’s definitely a economical reason to seem at bringing it in-house.”

Brian Shaffer, vice president for functions and quality at Far better Edge, extra that you also need to have to contemplate the anticipated volumes of particular coatings. “Recipes are extremely high-priced, specially in the significant-effectiveness arena we like to play in. So we have to do plenty of tests to establish the recipe is really worth it to our customer’s base line, and ask ourselves if we will have more than enough quantity to fill the unit to make it worth running.”

For illustration, said Shaffer, in late 2020 Better Edge invested in an Oerlikon Balzers arc engineering coating device with “TiN, AlTiN, AlCrN, and TiAlN recipes that authorized us to continue to keep 99 % of our small business in-residence. We nevertheless have the odd circumstance of very very long instruments that require to be shipped out, or a recipe we don’t provide, these kinds of as TiB2 or diamond.”

So is it worthy of including much more to the combine? Shaffer pointed to Balzer’s Tisaflex, which he stated had tested prosperous “in hardened steels and other tricky to machine materials. Which is one more recipe we may possibly one particular day take into account bringing in-home if we have sufficient demand.” The lesson in this article is that price considerations go over and above having a vessel.

Accomplishing cleanliness is one more value consideration, observed Shaffer. “We discovered that investing in a outstanding cleansing unit can help greatly in lowering coating vessel downtime by lowering arcing problems.”

Ideally you’d physically isolate coating from grinding, Lake added, since the latter puts particulates into the air. Normally, “you operate the higher risk of coating voids on your tools, mainly because the particulate will get on your applications. They go into the chamber, and then the coating doesn’t adhere. But we have clients that have coating devices maybe only 20 ft (6.1 m) from the grinder and they are nonetheless prosperous. We would advise a separation. But we also know occasionally fact does not permit that to transpire.”

Lake listed manage of the source chain as the 2nd most important issue in determining whether or not to coat in-house. “That way, the resources under no circumstances depart their facility, they never ever leave their handle, they shorten their lead periods. That is frequently a purpose.” Shaffer enthusiastically agreed: “Full handle of the course of action offers us a competitive advantage—being equipped to give much better guide moments. We just started off a system we connect with ‘Rapid Edge’ that gives high-efficiency coated specials in just 3 days.”

The third aspect to contemplate, according to Lake, is the means to establish proprietary coatings. He defined that agreement coaters are extra or a lot less forced to give regular products. “We really do not know what’s coming by way of the doorway every working day. … We can make tweaks with our pretreatment, our write-up remedy, or cleaning, relying on the measurement of the instrument and the geometry, to improve in different methods. But we really don’t have the identical versatility as a instrument company.” Lake included that there also isn’t a enormous variation concerning resources accessible from the competitive coaters. While, “when you deliver coating in house, you can do whatever you want. And with HiPIMS, you can sputter pretty much any factor on the periodic table.”

CemeCon’s president, Marjorie Steed, noticed that the extreme competitive strain brought about by the COVID-19 pandemic pushed device manufacturers to request new methods to distinguish themselves. “They requested, ‘How can we market our specialty merchandise? How can we show that our instruments conduct superior than right before, or greater than our opponents?’ This look for for new technological innovation led to a surge in desire for the HiPIMS procedure, and it has ongoing as issues shift forward.”

Proprietary Coatings

One particular business that you could say is obsessed with producing proprietary chopping-resource alternatives, to involve coating, is Sandvik Coromant, whose U.S. headquarters is in Mebane, N.C. The company’s Inveio coating takes advantage of a patented chemical vapor deposition (CVD) process to manipulate the grain construction these kinds of that it is “more perpendicular than any other aluminum coating on the sector,” according to Doug Evans, growth specialist. This uniformly perpendicular construction is much better than other CVD coatings, he reported, applying a distinctive illustration. “If you lay an egg on its aspect and implement tension to it, you’ll conveniently split it. But if you can stand that egg up, you get a lot much better compression forces and it normally takes a large amount more strain to crack. The exact is genuine if you can get that aluminum grain composition to stand straight up.”

Evans mentioned Inveio coatings can consist of numerous combos of titanium aluminum nitride, titanium chromium nitride, and aluminum oxide. Inveio is utilised for indexable inserts, the place CVD predominates. Evans described resource lifestyle improvements of 30 per cent to 50 %, strictly because of to the coating. For solid-carbide applications, the place a thinner coating is essential to protect a sharper cutting edge, Sandvik Coromant has a proprietary PVD method identified as Zertivo. The touted reward again is the capability to manipulate the coating process at the micro stage. This is reported to generate enhanced adhesion involving substrate and coating, optimized for every grade. Listed here it is titanium nitride, or a titanium carbon nitride coating. “We’re starting off to see some aluminum oxide form coatings with the PVD processes,” Evans reported. He extra that Zertivo is now getting utilized to all new carbide grades.

Sandvik Coromant not only patents its coating procedures, the business also builds its own coating vessels (not to mention creating specialised pre- and write-up-processing routines). Evans claimed 90 % of the applications Sandvik sells have been coated utilizing its individual equipment.

New, Thicker Coatings for Tricky Apps

As mentioned in the 2019 article, PVD is a greater method than CVD for a quantity of reasons—unless the software demands a thick coating. Lake stated that’s simply because worry builds inside a PVD coating as it will get thicker, and that potential customers to very poor adhesion and premature failure. “The arc approach has normally topped out at concerning four to five microns, until you did specific issues to additional ease the pressure. Standard sputtering maxed out at eight, perhaps ten, at the absolute most.”

But now—and you probably observed this coming—CemeCon’s HiPIMS is in a position to reliably obtain a 12-µm thick PVD coating. Steed said which is for the reason that CemeCon is uniquely in a position to synchronize the cathode pulses with the substrate table, thus “actively running and limiting” the residual stresses of the coating. “We’ve even tested coating as thick as 25 microns,” included Lake, “though not in output. Even 12 was unheard of as lately as 3 years ago.”

Steed discussed that this capability is primarily beneficial for coating the indexable inserts used in the hefty-duty machining of rails, switches, pipes and crankshafts, as perfectly as in the rotary peeling of solid iron and ferrous supplies. “These operations frequently call for a huge number of chopping inserts able of holding up to optimum operating speeds and furnishing large-excellent machining. Better coating thicknesses appreciably prolong their tool life—the important to financial performance. The correlation in such apps is virtually linear—and that is in which this coating, which we phone FerroCon Quadro, comes into participate in.”

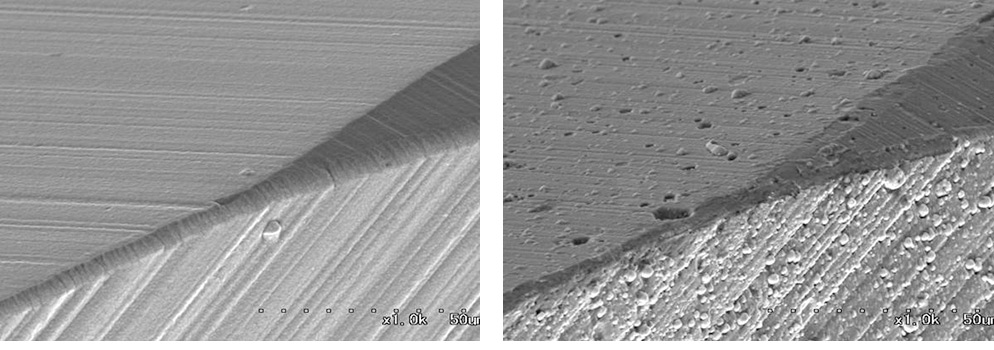

Steed also observed that in addition to being thick and rough, the FerrCon Quadro coating is quite smooth and the thickness is evenly dispersed, which supplies the best possible use resistance. In reality, it appears smoothness is a feature of not only HiPIMS, but CemeCon PVD coatings in common. Shaffer stated they have an more mature, pre-HiPIMS, CemeCon sputtering unit that “still outperforms the Oerlikon Balzers in programs wherever we need an exceptional surface area finish. We’ve found this with 7 flute ending endmills and some reaming apps.”

A Multi-Material Winner

Initially created for the hardened steels utilized in mould building, CemeCon’s SteelCon coating is now currently being used broadly, described Manfred Weigand, products supervisor for round applications. That contains stainless steel, nickel-primarily based alloys, titanium alloy, quenched and tempered metal (42CrMo), and cold-perform metal (1.2379).

Weigand attributed this success to SteelCon’s excellent thermal security and insulation, which “hardly lets any heat into the tool, but dissipates it by using the chip. This is especially advantageous for products that are on their own incredibly lousy warmth conductors, this sort of as stainless steel, nickel-primarily based alloys and titanium. Without having SteelCon, the significant temperatures that inevitably crop up through machining of the tricky supplies would damage the tool and embrittle the carbide.” Like other HiPIMS coatings, SteelCon is “highly have on-resistant,” due to the excellent adhesion of the coating and its high hardness and toughness, mentioned Weigand. “This combination of homes final results in drastically longer instrument lifetime and superb machining success.”

In one comparison (a 6 mm carbide endmill machining 62 HRC chilly-get the job done metal, with vc = 170 m/min, fz = .11 mm, ae = .05 mm, ap = .05 mm), the SteelCon coated resource lasted 1,050 minutes, vs . a competing TiAlSiN-coated tool’s 590 minutes, and an AlTiN-coated tool’s 405 minutes. In common, said Lake, SteelCon delivers “the capability to run resources wherever from 10 to 30 % longer than even our prior coatings, or run 10 to 30 p.c more rapidly than what they have been doing.”